product

Base oil: HR100、HR101、HR102、HR103、HR104、HR105

Vacuum pump oil: HR1506、HR1514、HR1525

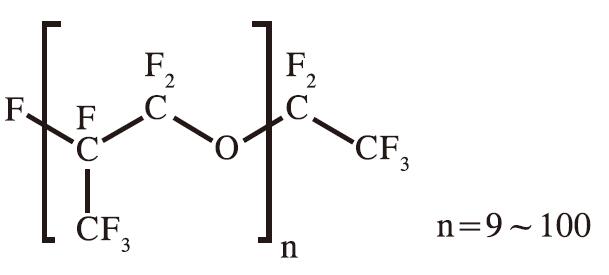

Perfluoropolyether oil is a colorless, transparent liquid at room temperature. It is resistant to high temperatures, chemical corrosion, oxidation, and radiation. It is primarily used as a lubricant and vacuum pump oil. Due to its extremely high stability, safety, and particularly its remarkable reliability under harsh conditions, no other working medium can match perfluoropolyether oil in such demanding environments.

| Characteristic | Conventional Lubricants | Perfluoropolyether Oil |

| Oxygen | Slow oxidation, producing acids or oil sludge; severe oxidation can lead to fire or explosion | Non-reactive, non-flammable |

| High Temperature | Rapid oxidation, carbon build-up or coking; accelerated evaporation and leakage | No carbon build-up, low volatility, and minimal loss |

| Water or Humid Environments | Insoluble in water | |

| Chemicals | Corroded by acids, bases, organic solvents | Chemically stable |

| Contact Components | Corrosion of sealing materials, lubricant leakage, equipment damage | Wide material compatibility, non-corrosive |

| Base oil performance | HR100 | HR101 | HR102 | HR103 | HR104 | HR105 |

| Applicable temperature range℃ | <-70~66 | <-70~104 | <-63~132 | <-60~154 | <-51~179 | <-36~204 |

| ℉ | <-94~150 | <-94~220 | <-81~270 | <-76~310 | <-60~355 | <-33~400 |

| Viscosity,cSt,ASTM D445 | ||||||

| 20℃(68℉) | 7 | 16 | 36 | 80 | 180 | 550 |

| 40℃ (104℉) | 4 | 8 | 15 | 30 | 60 | 160 |

| 100℃ (212℉) | — | 2 | 3 | 5 | 9 | 18 |

| ASTM D2270 | — | — | 29 | 92 | 124 | 134 |

| Pour point ASTM D97 | ||||||

| ℃ | <-70 | <-70 | -63 | -60 | -51 | -36 |

| ℉ | <-94 | <-94 | -81 | -76 | -60 | -33 |

| Density, g/mL | ||||||

| 0℃ (32℉) | 1.87 | 1.89 | 1.91 | 1.92 | 1.93 | 1.94 |

| 100℃(212℉) | 1.67 | 1.7 | 1.72 | 1.74 | 1.75 | 1.76 |

| Evaporation loss, ASTM D972, 22 Hourly quality loss( wt%) | ||||||

| 66℃ (150℉) | 11 | 2 | 2 | 1 | 1 | 1 |

| 121℃ (250℉) | 87 | 35 | 20 | 7 | 3 | 2 |

| 204℃(400℉) | — | — | — | — | — | 10 |

| Applicable temperature range℃ | <-70~66 | <-70~104 | <-63~132 | <-60~154 | <-51~179 | <-36~204 |

|

Vacuum pump oil performance |

HR1506 |

HR1514 |

HR1525 |

|

Viscosity,cSt, ASTM D445 |

|||

|

20°C (68°F) |

60 |

140 |

250 |

|

50°C (122°F) |

15.5 |

32 |

52 |

|

100°C (212°F) |

4.1 |

7.2 |

10.6 |

|

Pour point ASTM D97 |

|||

|

° C |

-60 |

-54 |

-48 |

|

° F |

-76 |

-65 |

-54 |

|

Density, g/mL |

|||

|

20°C (68°F) |

1.88 |

1.89 |

1.9 |

|

50°C (122°F) |

1.82 |

1.83 |

1.84 |

|

100°C (212°F) |

1.73 |

1.74 |

1.75 |

|

200°C (392°F) |

1.54 |

1.55 |

1.56 |

|

Evaporation loss ASTM D2595, 22Hourly quality loss (wt%)121℃ (250℉) |

|||

|

121°C (250°F) |

6.5 |

1.3 |

0.6 |

Hydrofluoroethers are compounds composed of hydrogen, fluorine, oxygen, and carbon atoms, featuring an ether structure.

Hydrofluoroethers are compounds composed of hydrogen, fluorine, oxygen, and carbon atoms, featuring an ether structure.

Perfluoropolyether (PFPE) fluid is a type of PFPE product characterized by low polymerization degree, low molecular weight, low boiling point, and low viscosity